By Chelsea Yates

Photos by Mark Stone / University of Washington

The MILL provides UW students, staff and faculty access to cutting-edge professional equipment, workshop space, an educational wet lab and classroom / meeting space.

This fall the UW welcomed a new makerspace: The McCarty Innovation Learning Lab (MILL). Located on the north side of campus in the newly-opened McCarty Residence Hall, the hands-on workspace gives UW students, staff and faculty access to cutting-edge professional equipment, workshop space, an educational wet lab and classroom / meeting space.

Students can safely learn basic machining concepts with equipment such as this Othermill desktop CNC machine, used to create circuit boards and cut aluminum and acrylic parts.

Undergraduate Kyle Luiten explains the Epilog Fusion M2 laser cutter. The MILL’s staff provide equipment and safety training throughout the year.

A collaboration between the UW College of Engineering and Housing & Food Services (HFS), The MILL is the second residence hall-based makerspace on campus. The other, Area 01’s Dabble Lab, opened in Autumn 2015 in Maple Hall.

“Our partnership with HFS is helping to transform how we educate students at the UW,” says Brian Fabien, associate dean of academic affairs for the College of Engineering. “By making it more accessible for students to practice engineering together in their living communities, we are laying the groundwork for an innovative approach to engineering education.”

To deepen the campus residence hall experience with the academic mission of the UW, HFS has established six Living Learning Communities (LLCs) across campus, of which engineering is one. In Maple Hall, which houses a LLC of nearly 800 engineering undergraduates, students can live and learn alongside other engineering students, attend engineering classes, use the makerspace, and participate in on-site career exploration events organized by College of Engineering staff.

Mechanical engineering senior Kaiyu Shi programs the Stratasys F170, a professional grade high-quality printer that can produce parts with an accuracy of +/- .200 mm (.008 in).

The MILL houses several sewing machines and a serger sewing machine. It also has a 10-needle professional embroidery machine that can stitch at maximum embroidery speed of 1000 stitches per minute.

Because of the success of the Maple Hall collaboration, when Fabien learned of plans to build McCarty Hall, he approached HFS about the possibility of establishing a makerspace there as well.

“HFS leadership was enthusiastically supportive right from the start,” Fabien says. “They truly understand the value of integrating living and learning on campus, and we are thrilled to grow our partnership with them through The MILL.”

Undergraduate Shiraz Shahukar operates the Potterbot Ceramic 3D printer, a machine that prints ceramic materials with complex geometry. The parts are then fired in The MILL’s kiln so they can be painted or glazed.

Students can access equipment, such as the machine on the left, to print and cut vinyl. The UV printer on the right can be used to print and emboss logos, lettering and other high-resolution images on just about anything.

Encompassing 8,000 square feet originally intended to be a fitness center, The MILL is a high- and low-tech environment that features a variety of tools and resources: 3D printers, laser cutters, advanced sewing machines, and a kiln. Fabien says that it’s unprecedented for students to have nearly unlimited access to the same equipment that professional engineers use regularly in industry.

Makerspace staff — including two full-time employees and about 50 part-time students — offer classes and equipment training at both The MILL and at Area 01 throughout the academic year. Classes at The MILL include introductions to CNC milling, 3D printing, embroidery and sewing, metal and laser cutting, and UV printing, to name just a few.

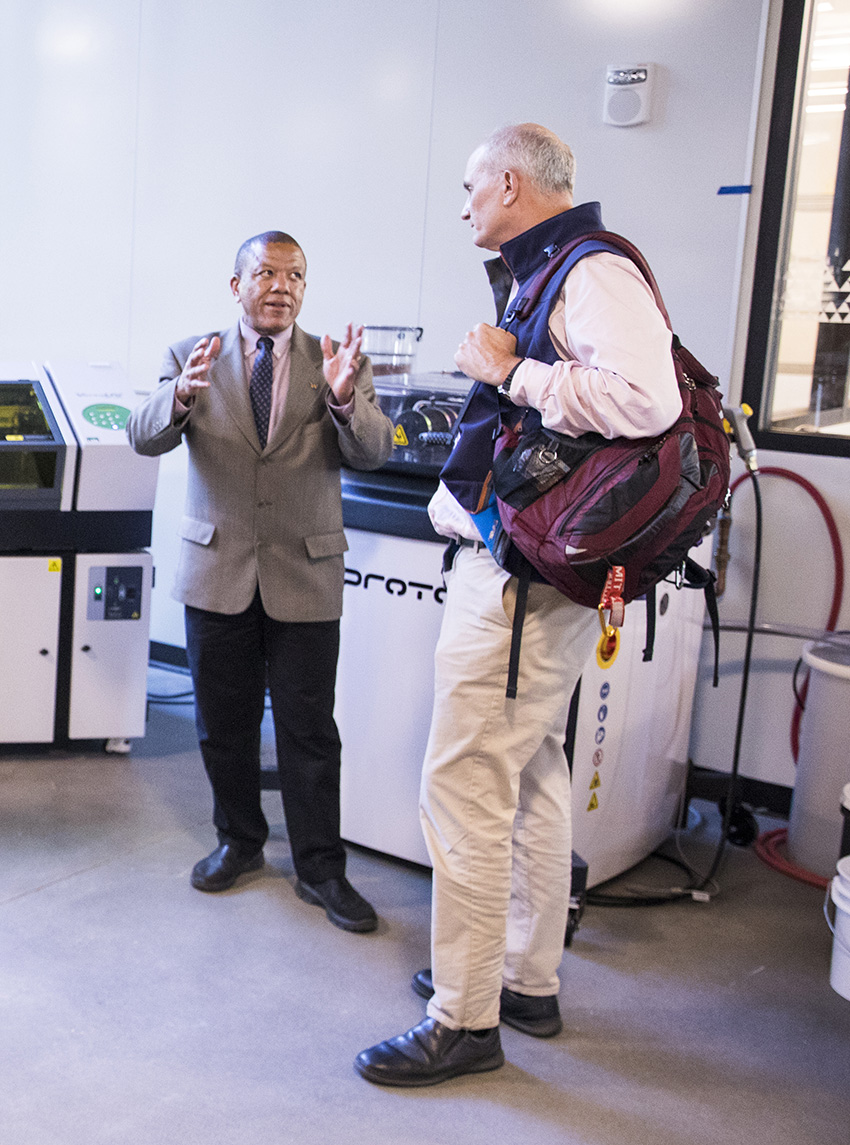

“By making it more accessible for students to practice engineering together in their living communities, we are laying the groundwork for an innovative approach to engineering education,” explains Brian Fabien, left.

“By making it more accessible for students to practice engineering together in their living communities, we are laying the groundwork for an innovative approach to engineering education,” explains Brian Fabien, left.

The UW Student Technology Fund helps purchase equipment for The MILL and creates access for the UW student community. The MILL is free to all students who complete the required safety training. UW staff and faculty may purchase a $25 quarterly membership to use the space.

In addition to industry-standard tools and equipment, The MILL features 700 square feet of meeting space, ideal for classes, workshops and events. By the end of the 2018-19 school year, more than a dozen classes and lab sections will have been held at The MILL. Academic and industry partners and registered student organizations are encouraged to host events there as well.

Since its opening, The MILL has already been used by nearly 650 students, many who have visited multiple times (for autumn quarter, The MILL reports about 3,000 total student visits). Fabien hopes that the UW community will continue to take advantage on the new space.

“The MILL is intended to be the home of experiential learning for engineering students but also a place where the entire UW community can collaborate, design and build," he says. “We cannot wait to see the creativity and innovation that will emerge from it.”

The MILL is open year-round from 8:30 a.m. to midnight Monday through Friday, and 1:00 p.m. to midnight on the weekends.

Find out how you can be a part of The MILL’s community.

Students gather at The MILL’s soldering station. The large tubes are exhaust for fumes that are emitted when soldering electronic components together.

Originally published January 3, 2019